| Parameter | Unit |

| X axis travel | mm |

| Y axis travel | mm |

| Z axis travel | mm |

| Table size | mm |

| Working table load | kg |

| Distance from spindle nose to table top | mm |

| Spindle speed | rpm |

| Spindle taper | |

| Spindle motor | kW |

| Tool magazine capacity | |

| Max tool diameter | mm |

| Tool length | mm |

| Tool weight | kg |

| Coolant tank system | L |

| Controller | |

| Machine weight | kg |

AF-1400 1400 800 800 1500x800 1000 800 10000 BT 50 11/15 24 ∅110 300 15 505 Fanuc Oi-MD 14000

NC Intelligence

AWEA’s self-developed intelligent i Console software enhancement system provides you with a user-friendly interface, real-time machine status information and dialogic functions. It not only effectively reduces complex working process but also increases intelligent machining abilities.

Multiple Functions Status Display

- Real time operation information

- Tool list

- Work piece measurement

- M code illustration

- PLC function

- Calculator

- CNC optimize parameter ( Opt. )

- Spindle thermal compensation ( Opt. )

Trouble Shooting

When the alarm appears, the program will display the breakdown cause and a troubleshooting procedure. Users can easily troubleshoot minor problems to save machine shutdown time.

Circular Work Piece Measurement

The circular work piece program can calculate the center coordinate of a work piece by measuring point A, B and C coordinates.

Rectangular work piece measurement

The rectangular work piece program can calculate the center coordinate and the slant angle of a work piece by measuring point A, B, C, D and E coordinates; the calculated center coordinate can be inputted into the work piece coordinate program ( G54~G59 ).

Manual Tool Length Measurement

After manually measuring the tool length, the controller will automatically calculate the tool tip position and input the data into the tool length offset table.

Adaptive feed control

Adaptive feed control is capable of real-time monitoring the spindle load to control the axial feed rate which effectively extends tool life, shortens rough cutting time, and detects abnormal cutting conditions.

CNC parameter optimization

From rough cutting to fine finishing, the operator can select various cutting modes based on the working condition, and then set the allowable error and work piece weight to obtain the optimum parameter.

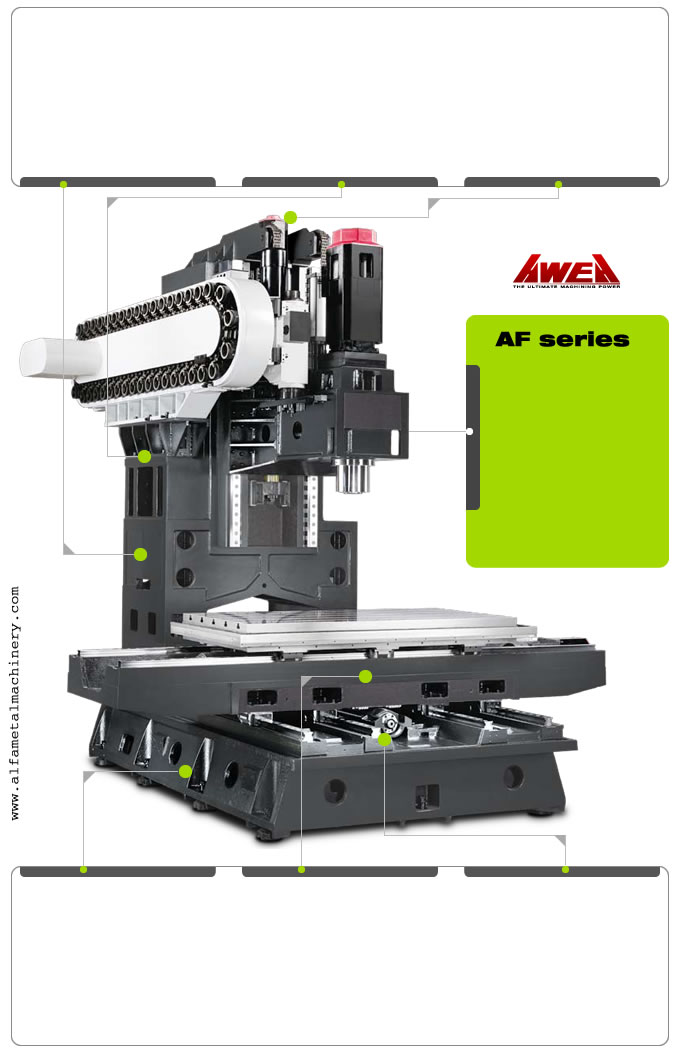

The Finite Element Method ( FEM ) provides optimal machine design and lightweight structure advantage while ensuring high rigidity of machine. The contact surface of the column and bed are all hand scraped to ensure precision assembly, strong structure and loading balance.

High rigidity roller type linear guide way which combines heavy cutting ability from ground box way and fast movement with low abrasion ability from linear guide way completely improves rigidity and control of machine.

Three axial system are adopted with FANUC αi absolute AC servo motor direct drive to provide great thrust and fast acceleration / deceleration movement. Plus, it efficiently decreases motor load and reduces generation of heat while maintaining the ultimate performance and accuracy.

High precision dual-nuts ball screw provides excellent heavy cutting rigidity while ensuring machining accuracy and extend durability of ball screw.

The standard swing-arm ATC with random tool change capabilities executes tool changes within 3 seconds (7 seconds chip-to-chip). Cycle times are dramatically reduced compared to machines equipped with carousel type ATC’s.

All series are standard with 24T arm type ATC system which can easily fulfill various types of processing needs.

Standard shortcut tool change function can shorten tool change time and increase working efficiency.

The tool magazine is supported by the column base, which increases stability and lowers the tool change vibration, while ensuring its precision ( AF-1250 ~ AF-1800 ).

All series are equipped with screw type chip conveyor. Single screw or triple screws type chip conveyors are adopted according to different models. The optional high pressure chips flush coolant system is also available.

AF Series machining centers are equipped with reliable, ultra-fast FANUC Oi controllers. Standard features: 10.4” color LCD screen, Ai-Nano, data-server and 512 MB ATA memory card.

Developed by AWEA and standard on all AF Series machines, the i Console software offers features like Automatic Feed-Rate Control, Parameter Optimizing Control, Simple Tool & Work-Piece Measurement, M-Code List, Troubleshooting List and much more to optimize performance and simplify operation.